Knowing different parts of a combi boiler and their functions is necessary to understand the operation of this complicated device and diagnose its problems.

Different boilers have different designs. Some of them have fans and some don't. Some have one heat exchanger and some two or more. We're going to introduce some parts and components which are common among all kinds of boilers.

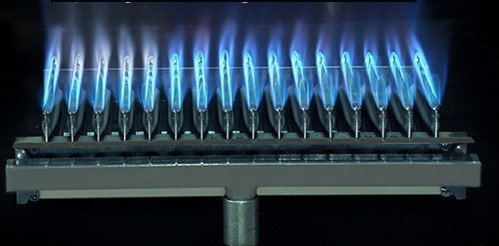

Burner

This boiler part starts the combustion inside the boiler. Different parts of the burner are:

- Manifold

- Nozzles

- Fins

- Gas control valve

The gas fuel and oxygen mixes with each other in this component and makes a flame which is the heat source. The fuel here is methane or ethane which reaches the boiler from an outside source. The combustion provides the necessary heat to heat up the water. The nozzle on the burner turns this fuel into the spray and ignites it to initiate the combustion inside the firebox.

Tip: a large part of burner in the boiler is made of aluminium and steel fins and the number of them is different according to the boiler capacity.

Combustion chamber

The fuel burns in the boiler combustion chamber. The chamber body is made of ceramic insulation and the temperature inside this boiler part can reach hundreds of degrees of centigrade. The heat produced in the combustion chamber is transferred to another boiler part which is the heat exchanger. Combustion chambers are divided into 2 group: closed combustion chamber and open combustion chamber.

- Closed combustion chambers

This kind of combustion chamber is used mostly in the buildings because it is safer than the open type. It has a double wall chimney which can both discharge smoke and suction oxygen. Required oxygen for combustion is got from the outside environment and the combustion gases are sent out through the chimney.

The size of chimney in these boilers is smaller and the fuel is completely burnt inside the combustion chamber. So, the energy is saved.

- Open combustion chambers

In this kind of boilers, the required oxygen for combustion is taken from the environment in which the boiler is installed and the combustion products are led outside through a normal chimney. Using this kind of boilers decreases the oxygen level in the environment. So, they should be installed in special locations. An appropriate chimney and a ventilation system are also needed in order to maintain fresh air and enough oxygen in the environment.

Tip: the combustion operation and producing combustion products in boilers with closed chambers are done in a complete closed space without any connection to the house environment. so, they are safer.

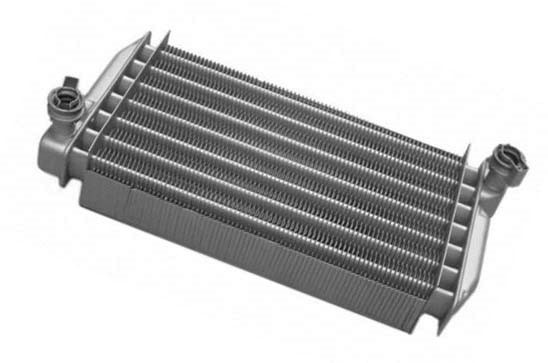

Heat exchanger

The responsibility of this component among other boiler parts is exchanging the heat as its name indicates too. In combi boilers, heat is exchanged between a hot gas and the water which circulates all over the house and inside the radiators. Combi boilers usually use gas as fuel. During the chemical reaction resulted from gas combustion with oxygen, a high amount of heat in the form of flame, water vapor and carbon dioxide is produced which are called the combustion products. These products flow to the heat exchanger and heat up the water inside the tubes.

The heat exchanger is just on top of the burner. The heat is transferred to the water inside the heat exchanger and then to the other parts of the house.

Gas control valve

The duty of this control valve among other boiler parts is controlling and adjusting the gas flow to the burner. This is done by electric signals going to magnetic solenoids or bobbins from the control board. The gas valve opens by receiving these signals and let the gas enter the burner. The temperature of the water inside the heat exchanger is adjusted by turning up and down or turning on and off the flow of gas by this valve.

Tip: the main duty of the gas valve is controlling the flame and heat of the boiler.

The boiler gas control valve is located under the combustion chamber and is usually made of aluminium. The gas hose of the boiler is attached to this valve.

Control board

This is the most important component among all burner parts and is in fact the brain of the boiler. The duty of the board is controlling different operations in the boiler, receiving different signals from different boiler parts as the input information and transferring them to other boiler parts as output operators. The number of boiler control boards is different according to the type of the boiler.

Thermistor

Thrmistor is a boiler electric part. It is made of a semiconductor, the internal resistance of which changes with the temperature change. Thermistor in combi boilers is an NTC type. It means its resistance decreases by temperature increase and vice versa. The electric resistance of this boiler part in 25˚C is 10 kohm. This boiler part measures the water temperature and reports it to the control board. So, it has a vital role in controlling the water temperature in the boiler.

Tip: the main duty of thermistor in combi boilers is converting temperature changes to electric current changes.

Thermistors are different in the appearance and the connection type.

Pump

The duty of the pump in combi boilers is circulating water to transfer heat from the main heat exchanger to other heat exchangers like radiators. The boiler pump is of centrifugal type.

The hot water moves in the system and the radiators, by the operation of the pump. It loses its heat and comes back to the boiler to heat up again. All this circulation is done by the pump which is an effective boiler part.

Note: in order to make sure about the appropriate productivity of the boiler and preventing the cavitation in the boiler pump and also protecting the main heat exchanger, there should always be a good pressure of water. This pressure is usually 1.5 bar in most of the boilers.

Relief valve

The heating circuits consisting of pipes, radiators and other boiler parts, are all effective in a normal pressure. If the pressure goes up for any reason, boiler parts especially the expansion tank are hurt and stops the heating system. So, the high pressure increase should be avoided. This is done by the relief valve.

The critical pressure for the combi boiler is usually 3 bar. If the pressure reaches 3 bar, the relief valve opens and drains some water from the system to reduce the pressure to the normal range. Then it closes.

The relief valve is made of different metals like bronze and aluminium and even plastic or stainless steel. But the spring inside the valve is usually made of stainless steel.

Combi boiler is an appliance made of a large number of components and parts. Here we introduced some of the main boiler parts which is just a drop in a bucket. If you need more information about this complex appliance, don't miss the boiler instructional video in HelloTechnic training system. Our experts and teachers give you the most detailed and updated information about boiler installation, service, troubleshooting and repair to make you a professional repairman.